|

Improvements

In Crop Nutrient Banding.

Exactrix

Tool Bars Produce Higher Net Margins.

Advanced Technology

Developed For Western Producers.

Page

1

Fall

Banding, Spring Banding and Side Dressing of NH3, Liquids and

Dry Fertilizer on the Great Plains.

Referred

to as two pass No-tillage farming.

Corn, Soybean, Wheat, Sunflower, Cotton, Milo and

Alfalfa.

Accomplished

with shank application, single disc application, and dual

purpose single pass seeders in shank or single disc.

The

improved margin is typically 12% or from $50 to $125 per acre

more net income. Exactrix

is not about N only applications.

Exactrix improves the margin every time with balanced

NPKS&Zn applications using No-tillage systems.

Page

2

Producers that band Exactrix TAPPS and TAPPKTS separately in a two

pass application of nutrients are located throughout the North

American continent.

Single pass application of nutrients reduces timing options,

complicates the machine, raises fertilizer costs and reduces the net

margin. However, single pass applications of TAPPS crystals continue

to be applicable based on farm size and the crop in production.

From

northern

Alberta at 58*N to

southern

Texas at 30*N nutrients are applied separately to assure better

timing and better location of nutrient bands.

Producers band TAPPS separately with row crop, corn in production.

Winter Wheat producers prefer to apply TAPPS twice with single disc

openers to get maximum yields. Large producers prefer to band

nitrogen stabilized TAPPS in the fall for dark northern spring wheat

production.

The reasons for banding separately from seeding are numerous.

The economics are better for some producers and the options are

greater. Some producers fall band TAPPS at nutrient rates that

allow either DNSW production or Corn production. The fertilizer

industry needs fall banding. The fertilizer industry cannot supply

high quality nutrients with superior accuracy if all the nutrients

are applied at time of seeding. The fertilizer industry must resort

to a

high volume,

tons moved system.

The high volume

approach

has poor accuracy using top dressed dry fertilizers and expensive

liquid nitrogen top dressed fertilizer.

Thus lowest cost of production and highest quality crop results in

applications using Exactrix Technology.

There is no argument from the Exactrix owners, “it works”.

Nutrients must have the option of being applied at the right time,

at the right depth and the right chemistry at a very reasonable

cost. Nutrients are always most crop effective when application is

made at 6 inch depths and the soils are moist. Dry fall soil

conditions may require shank type openers and a slight reduction in

efficiency of application compared to single disc application.

1. 1.

Corn producers do not want the complication of applying full season

nutrients at time of planting hybrid seed corn. Typically the planting

window is so short that most producers find it difficult to slow down

the planting operation for in- row starter fertilizer. The last

consideration is to apply full season nutrient rates with a 90 foot

corn planter.

|

Page

3

|

|

|

Another

reason to perform two passes is specialty crops and double crop

systems. A No-Tillage, 20 inch row spacing planter allows double

crop planting. The high speed Exactrix tool bar has banded TAPPS

at 6 inch depths on 15 inch centers.

|

Double

crop No-till production techniques require a high speed, single

disc tool bar for TAPPS nutrient application into heavy residue The

high quality, Triticale residue protects the germination of the

expensive Sunflower confection seed at Moscow, Kansas.

Thus double crop techniques are more successful when time

and moisture are conserved with a high speed tool bar.

Page

4

|

Double

crop sunflowers can be a money maker with proper management at

Moscow, Kansas.

2.

Strip

Tillage results in positional availability of nutrients such as

NH3, dry NPK, liquid

NPKS and micros.

Thus strip tillage production of corn is a two pass operation.

The 30 inch band spacing can be toxic if corn is planted on top

of the bands within 30 days of application. Thus Strip Till is a

preferred fall, late winter application to avoid corn root burn.

Single disc applications at 6 inch depths will not burn

corn roots on 15 inch spacing.

Page

5

3. Large

productive northern wheat and canola farms prefer to average out

their workload by fall banding nutrients with the established work

force. This allows absolute rapid seeding in the spring.

Fertilizer dealers applaud the technique.

Application of TAPPS into established winter canola provides much

higher nutrient efficiency. The producer can roll the dice once

the stand has been well established in October and November.

4.

Higher protein and

quality of Dark Northern Spring Wheat results with TAPPS fall

banding. The mobile nutrients are stabilized with crystalline

TAPPS using Thio-Sul®. In

the Pacific Northwest, and now in spring wheat production areas

of the Great Plains, fall banding of TAPPS and TAPPKTS for

spring wheat has proven to be consistently better in wheat

quality and protein. Such areas as Fisher, Minnesota and Steele,

North Dakota have proven significantly better crops with fall

banding on 12 inch centers. In 2014 yields were exceptionally

good with proteins in 14% to 15% range with fall applied TAPPS

on 12 inch centers.

Page

6

5. Typically nutrients such as

NH3 can be purchased in July at a much lower cost. Fall banding

can be implemented for spring cropping with the help of the

fertilizer industry. The fertilizer industry prefers to even out

the work load.

6.

Single

disc openers allow nutrients to be banded after seeding or

planting thus extending the fertilizer season. Winter

wheat responds well to nutrients banded into the growing crop

early spring outperforming liquid streamer bar application by

15%. Goodland Kansas studies show TAPPS to be

especially effective

in raising winter wheat yields.

7.

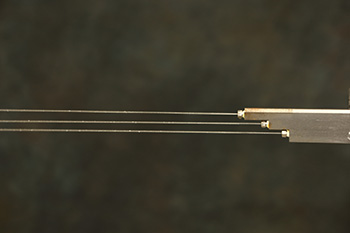

Producers

can now band nutrients in the same window as planting without

burning plant roots. Exactrix

technology of 15, 12 and 10 inch band spacing assures the

nutrients are balanced at 1% CV streaming flow application.

Thus it becomes economically powerful to band just in front of the

planter. Exceptional crop response results are achieved with Milo

and Corn utilizing 6 inch deep banding of TAPPS and TAPPKTS.

TAPPS

nutrient banding is time proven the most effective way to raise

high yielding dryland corn and Milo. Pre-plant banding of TAPPS

always exceeds center pivot application of nutrients.

8.

Banding

on 15 inch centers with Exactrix TAPPS and TAPPKTS has produced

improved margins of 12% and in several cases record yields in

every area of the Great Plains.

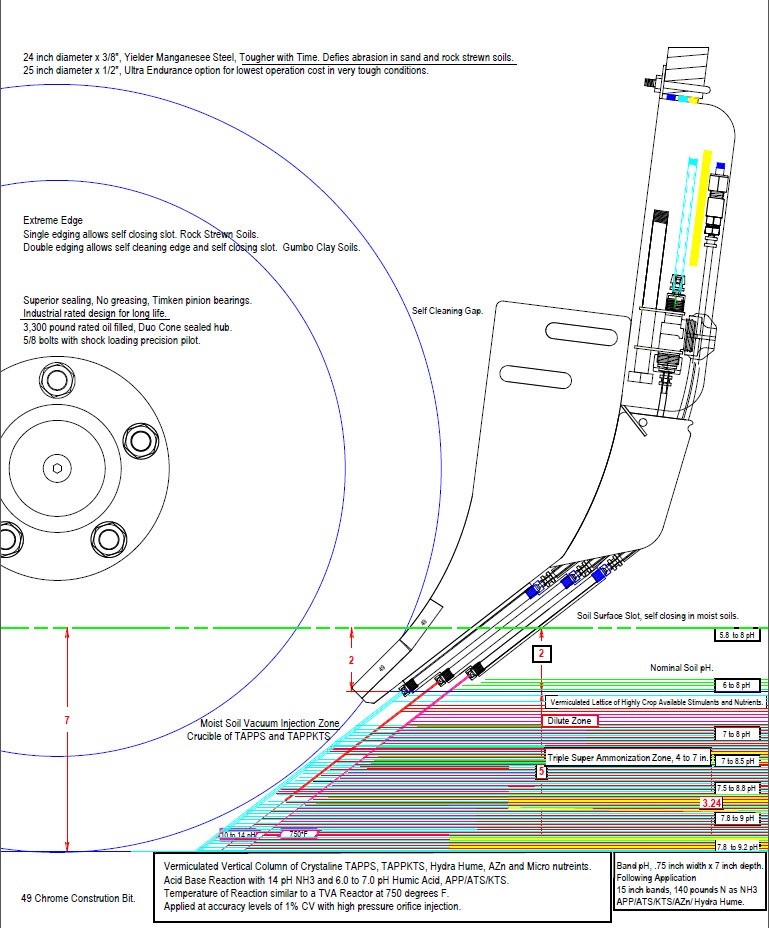

Exactrix TAPPS bands at 6 inch depths assure good

sealing. Phosphate is most efficient at the 6 inch depth in

Tri-Ammonium Phosphate Sulfate crystal. High

pressure, liquid streaming flow assures a uniform application.

Roots prefer liquid streaming applications because they are more

crop available and will not damage roots. Roots feed on an even

concentration of NPKS& Zinc producing better yields.

Page

7

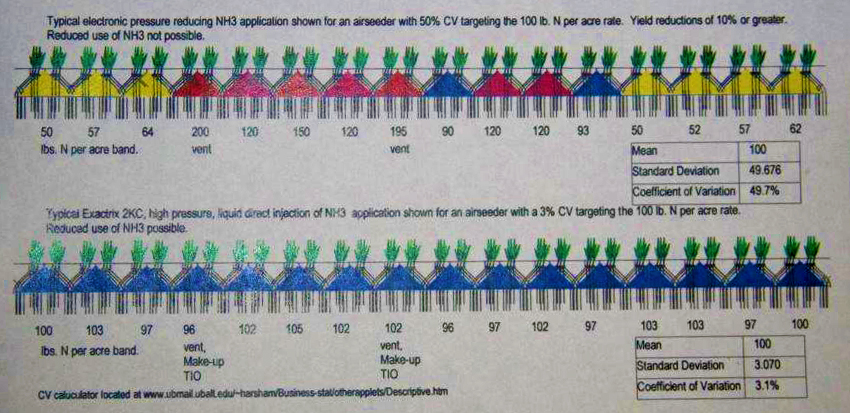

9.

Separate

application of nutrients with high quality 1% CV Exactrix

application systems allow much more effective management zones.

Typically VRT application is improved since the operator has

more time to pay attention to the application maps, pump rpm’s

and injection pressures. The accuracy or the

Coefficient of Variation

or

CV of the application improves the efficiency of the nutrients

and makes VRT successful.

10.

Large producers can rapidly expand their operations with

Exactrix adapted and or designed single disc openers and shank

type openers. Land lease opportunities can be much easier with a

separate banding operation. Fall banding of new land allows the

producer to free up his work load in the spring. Scientists

and producers agree that single pass works and two pass works.

Each producer has a different need.

Page

8

Nutrients

can also be banded into growing winter wheat with single disc

openers. High

quality stands results with virtually no damage to the emerging

winter wheat. Root

channels and surface residue remains effective in absorbing and

holding moisture.

Two

Pass No-tillage systems of winter wheat can be established in

the dry fall with higher yield potential. Winter wheat can be

seeded into dry soil at optimum seeding depths. It

is more important to seed the crop first in dry fall conditions.

The entire crop germinates the same day it rains. The two pass

system allows the single disc No-tillage applicator to locate

stabilized nutrients such as TAPPS much deeper into the emerging

winter wheat with virtually no crop damage. Banding

deep in dry soils is not efficient or desirable in many areas

and landscapes.

Another

major advantage is the single disc seeding and second trip

banding leaves residue on the surface to capture moisture.

The second single disc application of stabilized nutrients is

more crop effective than pre-plant banding or banding and

seeding at the same time. The crop effectiveness of expensive

nutrients is improved by banding into growing roots in moist

soil. Thus nutrients can be safely stored in the root zone in

moist soil conditions.

Shank

openers are not recommended for side dressing winter wheat or

spring wheat.

Page

9

On

the Snake River landscape of Lewiston, Idaho, established Winter

Wheat can also be fertilized in the late fall or early spring

with the single disc tool bar. TAPPS

with a balance of NPK and S does add to the yield potential. The

critical timing aspect requires the nutrients

can be banded just as

the crop breaks dormancy and machinery can be on the land.

On

the Snake River, Blue Mountain Landscape at Walla, Walla,

Washington. Exactrix

single disc tool bars band TAPPS at 6 inch depth into chemical

fallow at Walla Walla, Washington. May and June is the period

when nutrients are applied for fall wheat seedings. Seeding of

fall wheat occurs in October. With a No-tillage banding

technique it is possible to seed into a good moisture zone for

immediate germination.

Page 10

In

central Kansas winter wheat follows winter wheat. Standing stubble

maintains the summer moisture to the surface. Pre-plant banding with

single disc openers keeps the stubble up. The single disc seeder can

generate a high quality stand due to even moisture distribution. The

winter wheat seeding follows the banding in about 1 month. Approximately

50% of the nutrients are applied pre-plant.

The

final 50% is applied into growing roots once the stand is established

and the crop potential is known. Poor

weather conditions reducing crop potential allows the nutrients to be

stored in the tank and not in the soil. Keeping costs in line with

production potential allows greater profitability or an ability to

minimize the loss.

Further

reviewed, wet conditions due to heavy snows or rains may allow more

TAPPS nutrients to be applied to extract a higher yield potential of

winter wheat.

The final 50% investment is only made when the potential has been

revealed. Typically TAPPS banded in the soil at the 6 inch level will

outperform streamer bar application of solution 32-0-0 by at least

8-15%.

A

30 foot, high speed, Mustang tool bar on 15 inch centers is a good

choice for typical Kansas farms with 1,500 to 5,500 acres in a

rotation of Milo, Winter Wheat, Corn, Soybeans, Sunflower, and

soybean.

Page 11

Non-mobile

P and K nutrients can be banded into dormant alfalfa. This allows

older stands to be renovated and improved. Alfalfa can also be rotated

with No-tillage using pre-plant TAPPS banding techniques with a

typical No-till corn planter. Phosphate

and Potassium are twice as crop effective compared to top dressed

applications of dry fertilizer. Typical materials applied are 0-52-0,

10-34-0, Fluid Grade KCL. Alfalfa is the fourth largest crop at 17.6

million acres and 11.7 billion dollars in value.

Dry

fertilizer top dressing of Alfalfa also reduces stands producing poor

root development. Banding Alfalfa at the 6 inch depth develops roots

where fertilizer is placed allowing the plant to handle irregular

watering or drought pressure.

Smith

Center, KS, North Central Kansas, Banding into growing winter wheat

improves profits and allows much higher flexibility in growing winter

wheat. Milo is grown in

rotation with soybeans. A

40 foot tool bar is utilized by this large 7,000 acre producer.

Page 12

A

20 foot, 15 inch band center, three point tool bar.

Set up on 15 inch centers.

From

widths of 20 feet to 61.5 feet. From 1,000 acres to 14,000 acres

producers pick the tool to get the job done.

Almost always on 15 inch band spacing on the central Great

Plains is the common spacing. The 12 inch band spacing is utilized in

the Northern Great Plains where spring wheat is in rotation. A

61.5 foot tool bar can band 500 to 700 acres per day in irrigated

Nebraska. The producer can apply TAPPS right up to planting time.

Applying

at planting time on 15 inch centers assures maximum nutrient

efficiency with very low risk of leaching loss of N. Thus the

application becomes better than side dress applications typically

utilized in the area. The

Stabilized TAPPS assures nutrients will be supplied in the root zone.

Sandy soils with low CEC can be the exception.

Page 13

At

Shelton, Nebraska, TAPPS is applied right up to planting time with a

15 inch band spacing applicator.

The tool bar bands at depths to 6

inches.

At Deerfield, KS a track trailer allows liquid delivery of 4,000

gallons of NH3 and 2,600 gallons of liquid 10-34-0 and 12-0-0-26S.

Page 14

Exactrix

TAPPS banded on 15 inch band centers with Mustang openers. A 61.5 foot

applicator,

18.75 foot shipping width at 13.75 feet in height.

Liquid tanks are mounted on the tractor or the trailer.

A

powerful economic TAPPS banding combination for dryland, irrigated,

and double crop irrigated production.

Page 15

An April TAPPS application at the 6 inch depth into wheat stubble

resulted in a good stand of irrigated corn at Deerfield, KS.

A March TAPPS application into winter wheat at Marshall, MO, at

the Levee of the Missouri River.

Page 16

October TAPPS Application at 58 degrees North, Manning Alberta. Fall

banding for spring canola.

November TAPPS Application at

Seward , Nebraska

Page 17

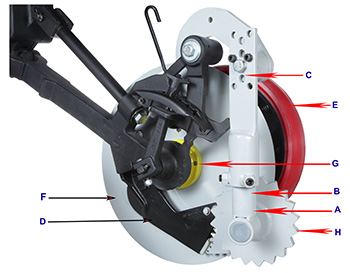

Low disturbance shank opener

from Horsch has proven successful.

The opener tolerates rocks and handles dry conditions well.

The fluted cutting coulter creates a progressive slot that

allows the shank to penetrate easier.

Lower soil disturbance is observed.

November

TAPPS application at Seneca, South Dakota.

Page 18

Horsch injection

system. Typically a

cutting coulter precedes the opener.

Flexicoil Stealth opener set up

for banding.

Typically no cutting coulter is used.

Page 19

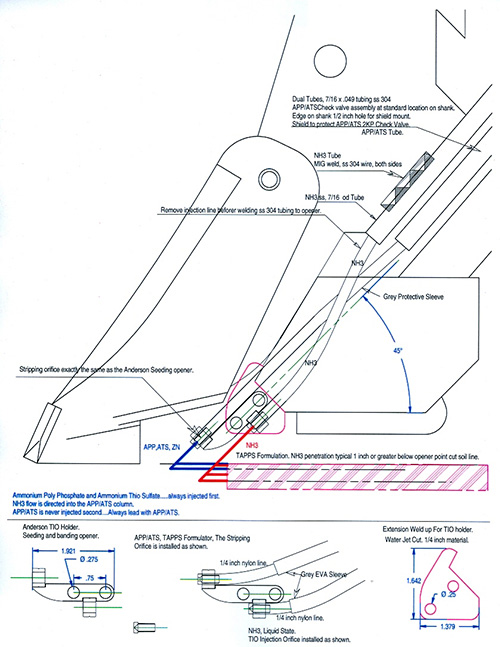

Single

Pass applications are desirable for Milo production.

Wing injection is utilized on 20 inch centers.

No-tillage

Milo allows maximum moisture infiltration. The proximity of the band

also allows triple chelated iron micronutrients on high pH soils. Some

of most efficient rates of nutrient application are accomplished with

the Deere 1990.

The

Deere 1990 can band only on 10 inch or 20 inch centers. The same

machine can wing inject TAPPS on 10 inch

seed row centers or 20 inch seed row centers.

The

machine can be used as a pre-plant tool bar for corn production.

Typically set on 10 inch band spacing.

The

Deere 1990 can be set up with large opener blades to improve

endurance. The blades are 5/16 x 19.1 diameter with a 1.25 inch single

edge.

The

opener can also be set up with polyurethane depth wheels.

A

good machine with lots of possibilities. The Deere 1990 is very

successful on the central Great Plains.

Page

20

The

Mid Row Banding Deere 1895 with AgPro individual seed run meters.

The single pass Deere 1895 is popular in the hillside area

of the PNW.

The

1895 can also be used successfully to fall band on 20 inch centers for

corn production in North Dakota.

Page

21

Sandy

soils with low CEC require side dress applications and pre-plant

applications at Yuma, Colorado.

Mustang

openers require less

horsepower than shank openers and will band up to 7 inches in depth

without Exactrix Gyro Counterweights.

Test,

Test, Test….USDA-ARS, Plot Drill at 15 feet.

Click on image to see video

Page

22

Page

23

|

See more Exactrix Videos HERE

http://exactrix.com/EOYT.htm

Meeting

your formulation needs.

www.exactrix.com/TF.htm

Picking

your metering systems.www.exactrix.com/EPM.htm

Need

more information on advanced crop production.

www.exactrix.com/EWAC.htm

For

More Information:

(509)

254 6854

|