|

Return To Main Page

Improving Yields at Beemer,

Nebraska along the Why is Fall Banding with Exactrix® Mustang so good?

Exactrix® Plots a Solution.

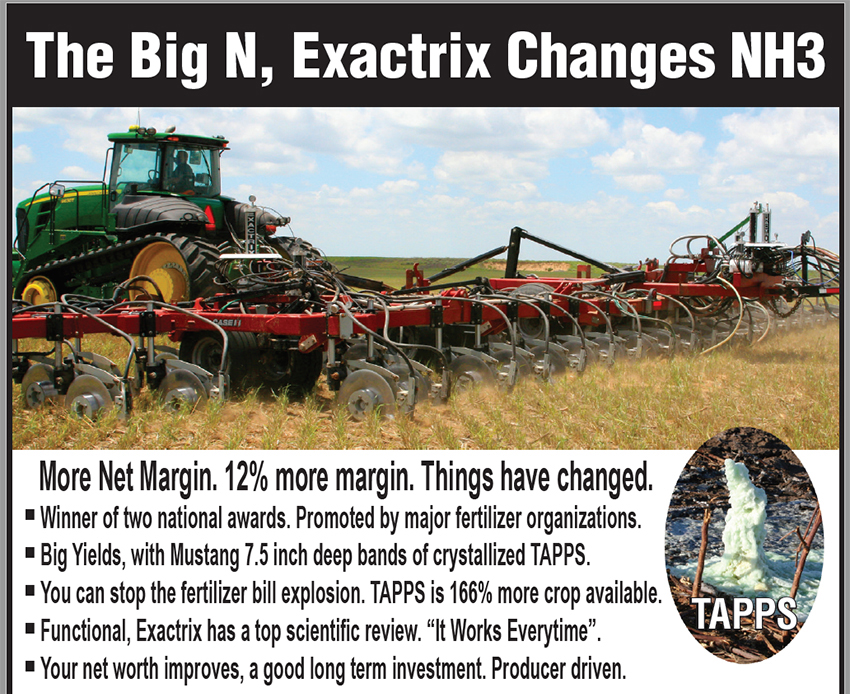

It takes Less to Raise More. Wherever you go in North America Exactrix works the same. Exactrix® in time proven testing, applies 166% more crop available N, 200% more crop available P, and 500% more crop available K. How can this be true? Correct chemistry, hydro mechanical 1% CV uniformity, and placed at 7 to 8 inch vermiculated depths for present and future root systems. “ No other nitrogen source when combined with KTS can get more soil moisture out of the soil and into the grain in irrigated conditions of Nebraska. This formulation of TAKTS greatly reduces irrigation costs per bushel produced.” “The only other nitrogen source in formulation of TAKTS that comes close is Aqua Ammonia.” GJS Kevin Medow of Seward/Tamora, NE on the Upper Big Blue NRD leads the way to the mystery of Exactrix® Fall Banding and seeking 300 bushels per acre. At Beemer, NE on the Lower Elkhorn NRD, the 300 bushel per acre mystery and discovery is inside the business opportunity. The business opportunity is KTS, Trafix Zn and Mn and reduced band spacing to 15 to 20 inch band centers at 7 to 8 inch depth. Why Exactrix® Mustang Fall Banding is an excellent management tool at Beemer, NE? A report for 2017/2018.

A note to Rick Engelmeyer at Beemer, NE following some top yields as high

as 292 bushel per acre average for his brother.

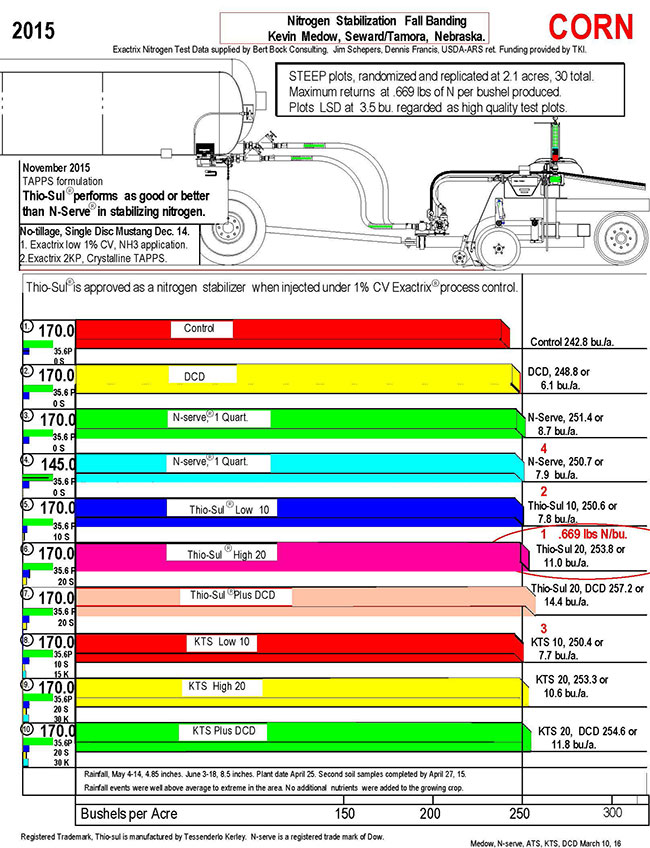

These

plots were very good (Low LSD at 2.5 acres each, 32 total) at

Seward/Tamora, Nebraska circa

Kevin Medow, and deserve your attention, 11.0 bushels per acre. With DCD

added, 14.4 bushels per acre. The DCD is not worth it as there a was

dollar swap at $15 cost. You could try a $5.00 rate of DCD and see where

that goes.

TAPPS

is Tri-ammonium Poly Phosphate Sulfate, TATS is Tri-ammonium Thio-Sulfate.

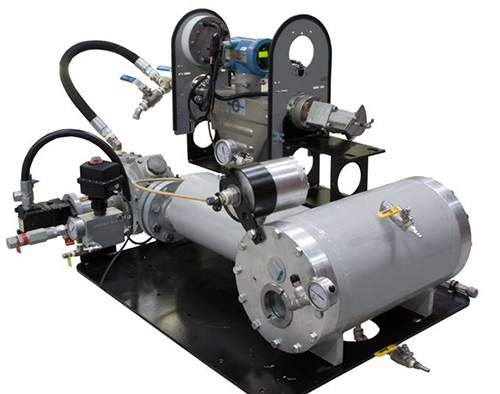

GJS, Jan. 16, 2021 Meeting the Needs or Rick Engelmeyer at Beemer, NE in Lower Elkhorn River, NRD of Eastern Nebraska. Following this recommendation from Guy Swanson and Dr. Jim Schepers, Rick Engelmeyer did make a change and installed the Exactrix 2KP formulator along with a new Ag Leader Controller from Chris Winklebauer, Central Ag. Rick’s Case 940, five section, 6 x 6 tool bar has twenty of the high speed P-51C Mustangs are spaced on 30 inch centers since he does not use phosphate. Soil test P is very high from the general manure history of Cummins County, NE. Irrigated production. The Case 940 tool bar can go 61.25 feet in 7 section on 15 inch centers. Rick’s machine does not have the 7 section, folding wings. The narrow transport machine is 5 section and can go to 51.25 feet on 15 inch band centers. Typically application speeds are between 7 and 8 mph. With proper power selection on smooth ground a 12 mph speed is possible. His twin tank trailers have bottom outlet valves and the applicator is 600 inches or 50 feet in overall width. The P-51C Mustang openers band very deep to a depth of 7 to 8 inches using 25 inch x 3/8 standard double edge openers. You can check this out at the enclosed video. The Injector foot runs at a 2 to 3 inch depth and injects into a vacuum going to an 8 inch depth. The opener self-seals at this banding depth. The injector foot has a replaceable wear bit, high carbon, RC 65, side sheets and threaded TIO’s. The threaded TIO’s have a different construction in a 2 piece design that develops a penetrating liquid stream to 350 psi. The band is applied at 1%CV in a vermiculated flow. The vermiculation improves the crop availability for the current crop and up to five crops to come following No-tillage Rotational Band Loading. Remember in high level test plots and over time in the field….the low application rate always wins with Exactrix. Learn Why More is not More. Less is More, If you would like to learn the practical side, you can review a 7 year study of Rotational Band Loading. http://www.exactrix.com/Broadcast_06_08_2020.html Rick has added as a second fertilizer product. This is a new product (10 years) released from TKI, KTS to many producers. This is a famous Award Winning Product developed by Dr. Tom Fairweather of TKI. You can finally get economic results with potassium for many years of No-tillage.

How well does KTS work in 300 bu/A

cropping? Testing and tissue sampling proved that Rick had one more hurdle to jump to cross into the 300 bushels per acre range. A July discovery, The need for K at the reproductive stage and S and Zn and Mn. WinField® helped with unique testing charts pointing to the K,S, Zn needs with the tissue testing. Dr. Jim Schepers oversaw the crop and reviewed the tissue samples. Using tissue testing timely circa WinField® proves successful and reduces cropping risk. https://www.winfieldunited.com/Winfield/media/images/images/2018-Tissue-Sample-Handbook.pdf Rick now applies KTS at seven gallons and KTS® and ATS at seven gallons on certain fields. KTS is now less than $4.00 per gallon….a 40 per cent price reduction over previous years. At seven gallons per acre KTS® his delivery is smooth at 140 to 180 psi injection pressures. The product that forms in a 1% CV band is Tri-Ammonium Potassium Thiosulfate plus micros Zn and Mn. TAKTS plus TraFix® Zn and when needed Mn. Ricks fall banding program starts November 1 with a corn on corn rotation is 140 lbs. N as NH3, 21 lbs. K and 14 lbs. S. and 1 gallon TraFix Zn. An additional micro package of Mn from Helena when Roundup is used. Since TraFix Zn with Asset Technology is new to you please review at https://helenaagri.com/products/micronutrients-specialized-nutrition/trafix-zn/ On soybean ground Rick reduces the N rate to 120 lbs. N. We are certain that no nutrients are lost below the root zone based on top yields and the high 4.5% OM at 25 CEC with good soil test P at 80 ppm typical. This fall Rick’s family purchased a quarter of land that joined his farm for $12,500 per acre. This is one the best farming areas in the USA. Exactrix® applications have been very successful in reaching 290 bushels per acre average in certain years on a pH of 6.5 to 6.8 and an OM of 4 to 4.5 per cent. The outlook or the next chapter is KTS® with micros Zn and Mn in the band….and this powerful nutrient choice will cover the bet for the following crop of soybeans. Tissue Testing with WinField® will need to continue. The only other addition to the machine performance would be 15 inch or 20 inch band spacing which the machine and tractor can do. Rick does apply manure and does do a light tillage program following manure application. A video is included. As Rick Engelmeyer says, “This is a faith based business”. Rick also spring bands TAKTS Zn, Mn. Here is a short video clip of 3 minutes. https://vimeo.com/bandbvideo/review/217536668/20cc923ba3 If you need more information go to www.exactrix.com/EWAC.htm. Several articles are available, The things you never knew about that allow producers to lead the pack. If you would like to review the crop in 2018 when the decision was made to add the second product system go here. http://exactrix.com/Broadcast_12_28_2018.html

Banding

deep….Fall Banding of TAPPS and TAPPKTS (NH3,APP,ATS,KTS, Hydra Hume) is

critical to make top yields.

Only

in North America...The uniform Exactrix® Anhydrous Ammonia when

combined with the

Snow

and ammonia does require No-till to evenly

distribute the snow fall across the land and of Not many people know that the slowly melting snow fall and snow pack in close to freezing conditions is critical to raise good crops. Argentina and Brazil are using No-till to raise good crops….but South America has no Snowfall and this means lower yields….and no Anhydrous Ammonia to drive the yields higher.

P-51 C

Mustang Openers help by lowering the uniform crystal bands deeper into the

soil to develop better roots in drought.

Here is the good News in the Early Years of Anhydrous Ammonia of the West Coast and also Mississippi.

Here is the incorrect News that eventually surfaced after Shell’s introduction by Mr. F.H. Leavitt of San Francisco.

Shell Engineers got

the 16 inch band spacing wrong.

Extension makes a

mistake.

Extension of Oregon State makes a very big mistake.

Ammonia goes to -70 F when placed in the soil as a gas.

Exactrix® only is applied as a liquid NH3 using a terminal injection orifice in a streaming flow and high 1% CV of application.

For certain the shanks of the applicator is greatly responsible for the Soil Erosion of the Columbia basin…it was not the ammonia that created the problem.

Erosion in the Columbia Basin increased dramatically in 12 years. Why? Arthur S King had no idea that Alfalfa would be plowed out on 30% to 45% of the land.

Something had to change….and by 1974 it did change forever. An article from the Washington Farmer

- August 1949

Your Great Plains Reporter.

|