|

Return To Main Page

Machinery Changes Everything Winston Mader, 2014 at Pullman, 76 years of Technology, Winston at 81. In 1938, this true D-6 tractor was delivered to Lewiston, Idaho to Owen Mounce, A Rodeo Star with cash, it was 1 of 2. It was not an RD-6, it was a D-6, Three Lunger. In 1938 half of the world’s supply of Diesel Engines were produced by Caterpillar Tractor Co. The sale of the Caterpillar 36 combine division (Holt) to John Deere fueled the Diesel Engine project at Caterpillar. It took a lot of capital to build Diesel Engines. Today this tractor runs well at Pullman, Wa….and has the original paint job(Lead Based). Winston is the second owner…..Winston Mader is operating the tractor with his son Steve on the combine header in 2014. A leveling John Deere 36B was built in 1952….with paint still on 80% of leveling rack teeth…meaning the land was not steep in its application at Pendleton. Genetics, Machinery, and Chemistry - Changes Everything.

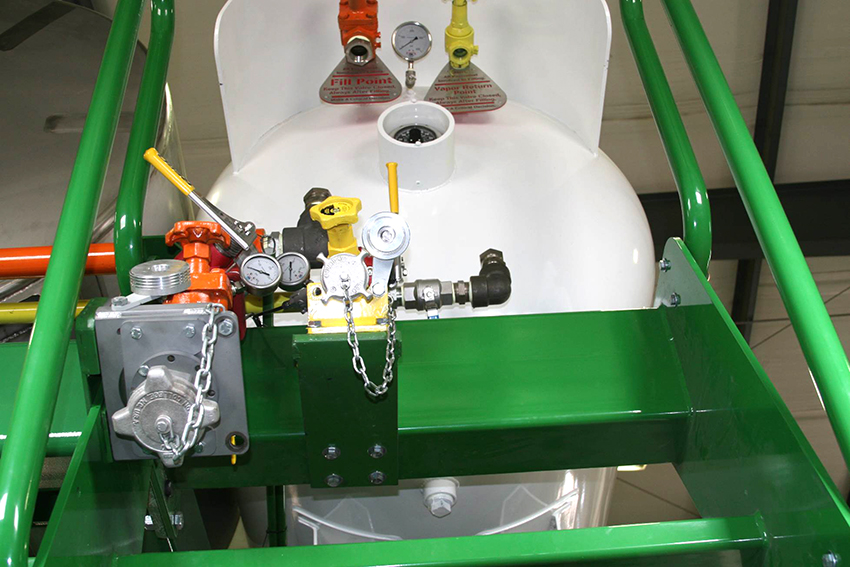

Exactrix Mustang 3015, Feb. 28, 19 at

Feterita, KS.

Ben McClure and Guy Swanson report in. Mustang openers at 25 inch diameter banding to 7.5 inch depth with 10 inch gyros. Crazy money.

The plant that Seaboard bought from Synata Bio. This is the original

Abengoa plant completed in 2014.

An organic matter deplete and destroy mission in the Dust Bowl? A

mining operation for sure in wind-blown soils. These soils eat OM at 1%

drop from 2.5% to 1.5% over the winter. These Southwestern Kansas soils

are high pH calcium carbonate based.

Developing Organic Oils, Plant and

Animal for Power Plants and Engines.

Here is a sure bet……

Hybrid Coastal Bermuda Grass. Fertilized Feb 14, 19. Banded TAPPKTS to 7 to 8 inch depths.

Ben

McClure.

TAPPKTS, AZn, 150 lbs. N as NH3, 5 gallons APP and 5 gallons KTS and micros.

Two different opener classes. Injection of TAPPKTS with P-51 C in

the back rank. Mustang TAPPKTS located in to anerobic zone at 7 to 8 inch depths, Banded Feb. 14, 19…picture Feb. 28, 19.

Hugoton, KS.

Banding in the Snow.

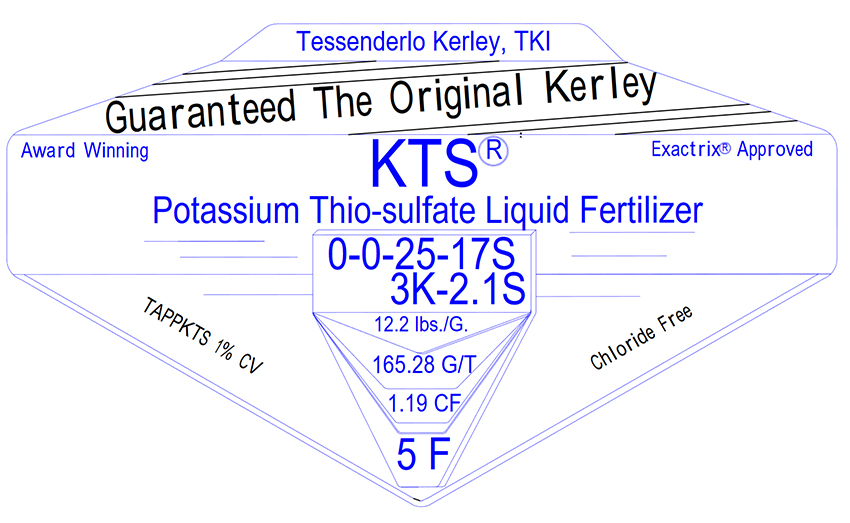

What

is KTS® ?. The biggest change to nutrient uptake and crop availability in

the last quarter century.

Yielder/Exactrix Steering Track Cart.

Yielder® Steering Track Cart, operates at 8 psi fully loaded and empty at 4 psi ground pressure. The Yielder steering system dictates a positional update to the 45 foot 5 section Mustang tool bar using a GPS dedicated receiver for sub 1 inch accuracy at the swiveling opener. A Mustang Tool Bar as a 4515 in 5 section is set up 45 feet on 15 inch band spacing. The tool bar is field expandable to 52 feet. A Great Plains acre eater at 10 mph... a rating of 500 acres per 11 hour day.

Fast and wide as a

5215 the Exactrix® Mustang Tool Bar and Yielder® Track Cart is capable of

a full section or 640 acres per 11 hour day. A 520 hp to 580 hp tractor at

52 feet. Set up for snow and born in a Bomb Cyclone of 2019.....This advanced tool is ready for Snow Banding at Fort Kearney, Ne or Shelton. Snow Banding In Nebraska conditions,

Advance designs in Binary Banding of TAPPS with micros at 7 to 8 inch depths in leveraged Seed Corn Production for Channel Hybrid Corn Seed.

Producing high quality hybrid seed that is “Power Packed” with the highest

quality and balanced nutrients available.

More news about Binary banding and Mustang Banding at 7 to 8 depths at www.exactrix.com/EWAC.htm Steering Ball and Socket. GPS corrected with second steering receiver.

Assembly of Steering, Yielder 2930 Track Cart, Mustang Tool Bar,

4515 in 5 section. A 520 hp Deere 9520RX. 24 inch belts.

Steering signals travel down the ball and socket “Reach”. The next Chapter. Exactrix Update. A Look. Pre- Plant Banding at 7 to 8 inch depths No-till directly under and to the side of each 30 inch corn row. Final Assembly Details, Yielder 2930 Track Cart.

Gangwish Seed Farm, Shelton, NE, Home of Channel Hybrid Seed. |

13

13